- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Size: 1

- Place of Origin: Anyang

- Brand Name: tiefa

- Model Number: 1

- Weight: 1.000 kg

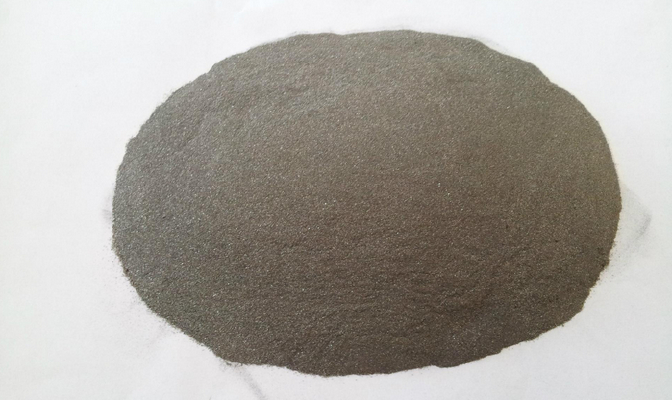

Ferroalloy powder as a structural material is divided into low alloy steel powder and high alloy steel powder. General respectively low alloy steel powder containing 1% ~ 2% of copper, nickel, molybdenum, and a small amount of alloy elements such as chromium and manganese, the water atomized pre alloy powders and restore diffusion of alloying powder two types. Gm varieties have a Swedish Distaloy alloy (Fe Cu - 0.01 C - 0.01-1.8 Ni - 0.5 Mo) and Astaloy alloy (Fe Ni - 0.05 C - 0.05-0.5 Mo - 0.25 Mn - 0.1 (Cr) and Japan's KIP alloy (Fe Cu - 0.02-0.1 C si - 0.02-1.5 Ni - 0.3 Mo), etc. Series of powder. This kind of low alloy steel powder compressibility good uniform, chemical composition, suitable for manufacture, high strength in the powder metallurgy parts. High alloy steel powder mainly include all kinds of stainless steel powder and high speed steel powder. Stainless steel powder for Fe - 18 cr - ni austenite size 8, porous filters used in the manufacture of powder metallurgy and corrosion resistant parts; Or the powder into the coating, the hot extrusion, rolling production tubing, rod and plate. High speed steel powder in addition to the Fe - 1.0 C - 6 w - 5 cr mo - 4-2 v (M2) and Fe - 1.5 C - cr 12 w - 4-5 v - 5 co T15 (America), and other general composition of casting high speed steel, and carbon, vanadium, cobalt were as high as 2.3%, 2.3% and 10% of high speed steel powder exclusive varieties. Aerosol low oxygen levels in the high speed steel powder (< 100 x 10), for spherical particles, powder into the package can be set, hot isostatic pressing timber. Water atomized powder high speed steel, high oxygen content (> 600 x 10), particles as the irregular shape, made by pressing and sintering of powder metallurgy parts. Ferroalloy powder also can be used as functional materials, such as magnetic Fe Si - 9.6-5.4 Al alloy powders and Fe - 23 co - 9 ni alloy powder; Permanent magnetic powder is used for sintered magnets Fe - al - July 14 cu ni - 37 co - 3-8 ti alloy powder. Emerging in the 1980 s and a iron base of rare earth permanent magnet alloy powder, the chemical composition of the typical Nd15Fe77B8 and Nd13Fe82B5 (both for atom percent). The former by directional crystallization ingot casting machine broken making, for the production of anisotropic sintered magnets, maximum magnetic energy product is up to 400 kj/m, the latter by rapid quenching preparing thin belt grinding, made of resin and rubber bonded magnets. Ferroalloy powder also can be used as the thermal spraying (welding) hard facing materials, such as Fe, 2 b, 3 si alloy powder, its low melting point (1000 ~ 1100 ℃), high hardness (HRC 45 ~ 50), can be used to improve the surface wear resistance or repair the size of the wear parts.

Copper alloy powders Have the brass (Cu - zinc), bronze (Cu, Sn, zinc, Pb, P) and copper (Cu - 18 ni - 1.7 zinc - 2 Pb) series, such as powder, especially with lead or tin bronze most varieties. Almost all can be made of copper alloy powder atomized powder legal system into the spherical or irregular shape particles. They have good strength, thermal conductivity, wear resistance and colour and lustre, can be widely used in the manufacture of mechanical parts, porous filters, oil bearing, decorations and the thermal spraying (welding) hard facing materials. High-lead bronze Cu -, Cu and pb powder - 24 pb - sn 4 powder, can manufacture bimetallic bearing shell. This is a more composite anti-friction material used in automobile.

Nickel alloy powders In the manufacturing of high temperature alloy materials, magnetic materials, and is widely used on the thermal spray coating. High temperature alloy powder containing chromium, cobalt, manganese, titanium, aluminium, niobium, zirconium and boron alloy elements such as the limitation of fortified atomized pre alloy powders and chromium, aluminum, titanium, yttrium oxide dispersion strengthened type mechanical alloying powder. The former such as the United States Rene95 (14 cr Ni - C - 0.1-8 co - 3.5 Mn - 3.6 W - 3.5 Ti Al - 3.5-0.1-3.5 B Nb - 0.05 Zr), used in the manufacture of high in esteem than aircraft engine turbine disc; The latter such as the United States of Incoloy MA956 (cr Ni a 20-4.5 - Al - 0.5 Ti - 0.7 Y203), used in the manufacture of gas turbine casing and flame tube. Nickel alloy powders and those of Ni - Cr - B - Si thermal spraying (welding) alloy powder, boron and silicon containing up to 2% ~ 2% respectively, the low melting point (1000 ~ 1100 ℃), can be in the process of acetylene flame or plasma flame spray to slag, is a kind of self fluxing alloy with good sex, more used for surface strengthening of wear-resisting, corrosion resistant coating. Nickel alloy (Ni_17Fe - 2 mo), also known as permalloy (USA), is a kind of high permeability function of ferromagnetic materials, usually by atomized powder legal system into a powder, the particle surface after insulation coating is suitable for manufacturing of induction coil magnetic core.

Cobalt tungsten cobalt chromium alloy powders have a series of Co - 32 Cr - 1.4 C - 6 W and Co - 0.5-25.5 C 2 fe Cr - Ni - 10.5-7.5 W. The former for the thermal spray welding powder for plasma spray welding parts surface under high temperature and high pressure, to improve its high temperature abrasion resistance corrosion resistance; The latter is used in the manufacture of high temperature alloy. In addition to Co - 26 cr - 5 mo powder, used in the manufacture of medical artificial joint. Cobalt alloy occupies an important position in the functional materials. Rare earth can use cobalt alloy powder or liquid phase sintering methods manufacturing permanent magnet. SmCo5 and Sm2Co17, sintered permanent magnet maximum magnetic energy product of up to 208, 256 kj/m, respectively.

Aluminum alloy powder By atomized powder method or mechanical alloying method, and the hot isostatic pressing, hot extrusion, hot forging processing fulfill density light metal alloy material. Aluminum alloy powder in three types. Room temperature high strength type varieties have Al - 6.5 zinc Co Cu - 2.5 Mg - 2.5-2.5-0.3 O zinc and Al - 7.5-2.5-2 Cu - 0.2 Zr - 0.2 Mg Cr corrosion resistant alloy powders and mechanical alloying A1-4 Mg - C - O dispersion strengthened alloy powder. High temperature and high strength type (working temperature of 170 ~ 300 ℃) varieties have Al - 8 fe - ce 8 fe and Al - 4-2 mo powder. High specific strength, specific rigidity type varieties have Al - 2 li powder. This kind of lithium aluminium alloy density can be reduced by 6% ~ 9%, than the modulus of rigidity can be increased by 19% ~ 30%. With aluminum alloy powder to produce high performance light metal alloy materials, used for aerospace, aviation, and auto industry on the different structures and components.

Titanium alloy powder by the method of rotating electrode atomization powder or inert gas atomization rule of law, its chemical composition have Ti - 6 a1-4 v and Ti - al - 6 v - 2 sn. The titanium alloy powder with hot isostatic pressing technology can be a forming with theoretical density near the end of alien artifacts and plate. These products have been in the aviation engine, used on fighter planes and helicopters. Titanium alloy powder can also manufacture medical bone.

Precious metal alloy powders Mainly silver alloy powders, number by ingot mechanical crushing or atomization law. Varieties have teeth materials. Ag - 5 cu - 26 sn - zinc powder; Ag - 50 w electrical contact materials, Ag, Mo powder and Ag, ni powder; And used for soldering material. Ag, cu 15-20 zinc - 20 CD powder, etc.

Tin alloy powders A slightly blue white luster of low melting point metal elements, within the compound is bivalent or tetravalent, will not be air oxidation, mainly oxides (cassiterite) and a variety of sulfide sulfur cassiterite (for example). Sn element symbol. Tin is a famous "hardware" -- one of gold, silver, copper, iron, tin. As early as in ancient times, people will find and use the tin. In our country, some of the tomb, and often find some to tin pot, tin tin candlestick and so on. According to research, Zhou Chaoshi in our country, the use of tin has been very popular. In Egyptian tombs, also found a tin of everyday products.

- Size: 1

- Place of Origin: Anyang

- Brand Name: tiefa

- Model Number: 1

- Weight: 1.000 kg